- Project Overview

- Project proposals

- Project Craft

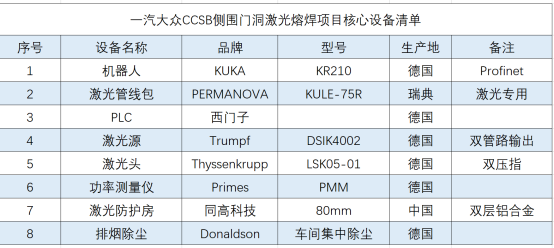

- Project equipment list

- Project site photos

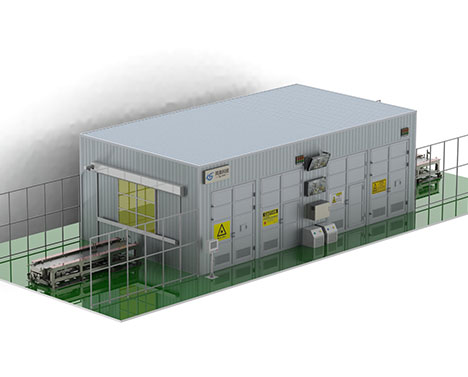

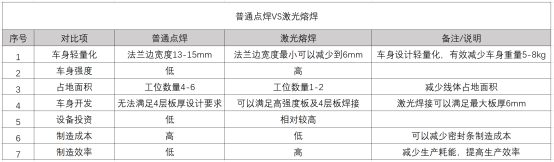

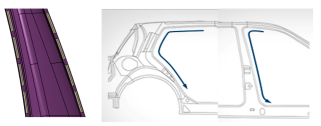

In April 2019, Tong Hi-Tech undertook the replication line reconstruction project of FAW-Volkswagen (Changchun Base) Welding and Welding Plant No. 2 and was responsible for the "turnkey project" of the new side wall door laser fusion welding station project for 3 types of vehicles including CCSB. The process was first developed in 2001 by ThyssenKnuber of Germany for a variety of high-end models of German Volkswagen and Audi. In recent years, it has been successfully introduced into the domestic market, mainly for the side panel inner and outer panel areas, which can realize multi-layer carbon steel plates. Compared with the narrow flange side of high-strength steel plate, compared with the traditional spot welding, it has many functional, technological and efficiency advantages:

該項目是長春一汽大眾二工廠的復制線改造項目,主要提升CC及邁騰等高端車型的產能,其中側圍門洞激光深熔焊工位位于主線補焊線上。

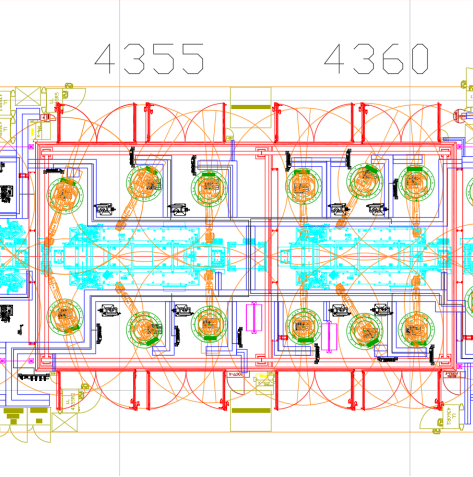

激光焊接房與激光源房采用分體式設計,激光源房坐落在單獨設計的鋼結構平臺上,激光焊房采用串聯雙工位布局,每個工位左右對稱設置了6臺激光焊機器人,大幅度地提高了自動焊接效率、減少了補焊線工位數量,同時也能作為設備故障互備的方案。

? 工位規劃50JPH,節拍CT=61.5s,預留提升60JPH;

? 工位規劃3+1車型,設備可滿足無限制車型導入;

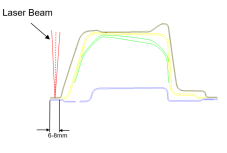

? 配合使用4kw激光器,焊接速度≥45mm/s;

? 焊接法蘭縮減50%以上,連接強度提升30%以上;

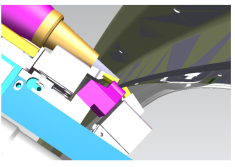

? 采用蒂森LSK05雙壓指激光熔焊頭,可實現多層板無夾具的焊接工藝,自帶的浮動功能,可最大限度的補償工件的誤差;

? 激光熔焊系統采用世界先進主流工藝設備配置,可實現高品質焊接質量要求;

? 工位采用同高科技自主研發的雙層鋁合金的防護系統,并通過德國TUV安全檢測及認證;

2D布局圖

項目采用一汽大眾激光焊接工藝標準,選用Thyssenkrupp雙壓指熔焊頭,配合高精度伺服控制雙壓指機構和控制系統,實時調整焊接壓指的夾緊力,調整板材之間的匹配間隙,焊接焦點尺寸為0.6mm,焊接速度≥45mm/s。

English

English 中文

中文